Back to the Basics of Pressure Sensitive Labels

July 29, 2024

What are Pressure Sensitive Labels?

A pressure sensitive label is a self- adhering label. With its “sticker-like” properties it will not need any glue to make them stick. All they need is pressure (hence the name!) and they will cling to the surface of your container.

These labels can be cut into a variety of unique shapes and sizes therefore they are versatile among markets. Some examples of common pressure sensitive label markets include beverage, household, cannabis, nutraceuticals, health & beauty, food, and much more!

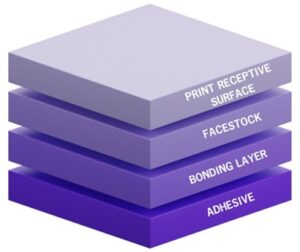

From top to bottom let’s talk about the label layers. First is a print-receptive surface that accepts inks and coatings to get your graphics and brand image on your packaging. Next, is the material of the label choosing between paper or film, that can also be referred to as facestock. After this comes a layer that bonds the top layers with an adhesive, which is the final layer. These adhesives range from ultra-removable (think of a Post-it note) to permanent. The label substrate with the adhesive is applied to a silicone treated liner that carries the labels for application.

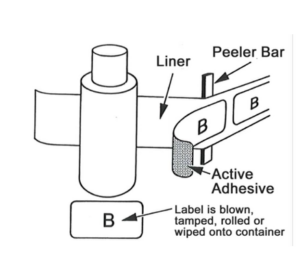

Pressure sensitive labels are one of the most common label applications. With these labels there is a wide range of application equipment, costing as little as zero if you want to hand apply each label. When a roll of labels are ready to be applied to containers, the roll is unwound over a peeler bar which separates the liner from the labels. From there it is directed towards a container where it is either blown, tamped, rolled, or wiped onto the container. Check out a diagram below for a visual of how these are applied to a finished product.

Use Cases

You can apply the labels anywhere on your product’s packaging as long as you have the right adhesive for the job. These versatile labels can be cut into any shape and size, making them a customizable canvas for your brand! Pressure sensitive labels have a wide range of use cases besides conveying branding on your favorite soap, food, or beverage product. They can also be used to get barcodes and QR code labels on to a product or object, create tamper evidence, as promotional stickers and more!

Customizing Your Label

When designing your label, you want your product to stand out on the shelf and capture consumers’ attention. With pressure sensitive labels there are countless ways to achieve this! From sustainable features to eye-catching embellishments, you can customize your labels to align perfectly with your brand identity. Here are some exciting customization options offered by Inland Packaging to make your label truly unique.

- Material Options: Ranging from white, craft, and metalized papers to clear or metalized films, this is the starting point to create a unique looking label

- Color Quality: You spend countless hours choosing colors to help convey your brand’s message, with decades of experience in custom color printing, we can help represent your brand with extended color gamut, spot colors, and more to fit your needs

- Shape: With tight cutting tolerance, Inland can provide labels in any shape

- Embellishments: Our state of the art equipment can provide endless combinations like tactile varnish, foil stamping, textured inks, super opaque white ink, and matte coatings. In addition, we offer cast and cure technology to create a holographic effect, texture or pattern on your label.

- Sustainability: Inland Packaging uses PureWash that separates the label facestock and adhesive from the PET or HDPE container under specific waste-processing conditions to help in the recycling process of your plastic container. We’re also experts in downgauging, or thinning of material, to reduce the overall amount of material used.

How Inland Packaging Can Help

With over 80 years of experience in the world of labels and packaging, we know how to navigate the waters! When you partner with Inland Packaging, you are supported by our dedicated Technical Support Team (available 24/7) who bring all the resources of Inland to your door. Supporting you as you optimize production using a new label, troubleshooting specific production issues, and everything in between. We’re passionate about labels and would love to answer your questions about all things pressure sensitive labels. Contact us below with questions or topics you want to know more about!